Bamboo

| Common Name | Bamboo | Japanese Name | Take |

|---|---|---|---|

| Scientific Name | Gramineae Bambusa Arundinacea | ||

| Fibre Length | Average 2.7mm (1.5-4mm) | Fibre Width | Average 15µm (10-25µm) |

| Fibre Ends | Pointed | Cross-Marking | Faint |

| Associated Cells | Large Pitted vessel elements and barrel or rectangular Paranchyma cells | ||

| Herzberg Colour | Blue | Graff 'C' Colour | Blue |

Notes:

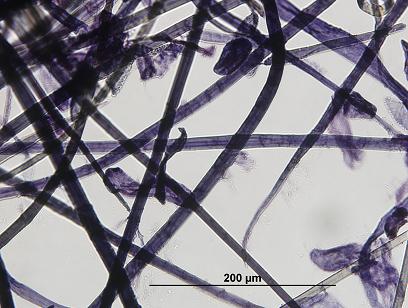

Fibres are long, narrow, thick walled, and usually have pointed ends, but also have blunt ends. Large pitted vessel elements are also present (See Image 1), with the maximum size being seen at 1mm X 250µm [14]. These elements contain longitudinal rows of pits and stain an orange or blue colour. Parenchyma cells are common, and are generally thick walled, barrel or rectangular shaped with pitting (See Image 2). Also present are long, thin, pitted parenchyma cells (See Image 2).

Abundant in China and Japan, this cheap, easily renewable and abundant fibre resource is widely used in paper manufacture, either solely or in combination with other fibres. It has been in use in papermaking from as early as 750AD in the mid-Tang Dynasty in China [25], although it entered into widespread usage as a substitute for hemp and rattan [25] from the Southern Song Dynasty (1127-1279AD). The three main varieties used for papermaking are known in Chinese as ch’ing kao, pai liao and huang liao [26]. Bamboo fibres are often added to improve the quality of the ink bleeding to papers containing Kozo or other longer bast fibres. Calligraphy papers made from bamboo are known as Toushi in Japan, and is appreciated for its warm, natural colour similar to aged paper and handling properties. The main source of bamboo is southern China, mainly Fujian and Zhejiang Provinces.

Traditional Processing of Bamboo Fibres

After harvesting, the bamboo that is about to shoot new leaves and branches is left to stand in pools of water for more than one hundred days. The bamboo is then washed and pounded to remove the outer green bark. The fibres are boiled in lime for up to eight days. After boiling the fibres are washed and the pulp is then boiled again with wood ash or lime, and washed and strained again numerous times. The fibres are then removed and pounded in a pestle until it has a clay-like consistency [24].

| Image 1 | Image 2 |

|---|---|

|

|

For information about this page, contact: Travis Taylor

Contact email address: travtora@gmail.com

Centre homepage: www.culturalconservation.unimelb.edu.au

Page last modified:

This page, its contents and style, are the responsibility of the author and do not represent the views, policies or opinions of The University of Melbourne.